In the rapidly evolving field of aerospace and unmanned systems technology, researchers are constantly seeking innovative materials and designs to enhance the safety, efficiency, and longevity of drones. A research team from the School of Synthetic Biology and Biomanufacturing at Tianjin University has made a groundbreaking breakthrough by developing a revolutionary “self-healing drone shell” that not only prevents icing but also features intelligent monitoring capabilities.

This multifaceted breakthrough, published in npj Flexible Electronics, is expected to address some of the most persistent challenges in unmanned flight — particularly under harsh environmental conditions where ice accumulation threatens flight stability and sensor integrity.

The problem of aircraft surface icing is well known, as it often compromises aerodynamic performance, increases weight, and impairs sensor functionality. Traditional de-icing systems rely on mechanical or thermal methods, which add weight, consume additional energy, and introduce potential points of failure.

The research team’s innovative approach reimagines the drone’s skin as a multifunctional material capable of autonomously repairing damage and adapting to the environment in real time, seamlessly integrating prevention, detection, and response mechanisms into the aircraft’s outer layer.

At the heart of this innovation lies a flexible, self-healing polymer composite that can restore structural integrity after sustaining damage — such as microcracks or abrasions that may occur during flights in harsh weather or upon collision with debris. The polymer matrix contains microcapsules filled with healing agents, which, when triggered by mechanical rupture, quickly release the agents to fill the cracks and polymerize to restore continuity. This mechanism extends the drone’s lifespan by preserving aerodynamic surfaces and protecting embedded sensors — all without the need for manual maintenance or replacement.

The anti-icing capability is achieved through an embedded network of nanoscale heaters integrated within the polymer skin. This network, composed of conductive nanomaterials such as graphene or carbon nanotubes, enables precise temperature regulation across the entire surface, preventing ice nucleation and buildup even in sub-zero conditions. Thanks to the distributed nature of the heating elements, the system operates with exceptional energy efficiency — activating only in areas where icing is detected or anticipated — thus conserving the drone’s power reserves for extended missions.

In addition to thermal control, the skin incorporates a suite of flexible sensors that continuously monitor environmental variables such as temperature, humidity, pressure, and icing. These sensors are interconnected through a stretchable circuit architecture, maintaining seamless connectivity even when the skin deforms. This independent monitoring system enhances situational awareness, allowing the drone to autonomously and intelligently adjust flight parameters or trigger protective measures in real time.

One of the most striking features of this drone shell is its ability to seamlessly integrate self-healing and environmental sensing functions with the onboard diagnostic system. The composite material works in tandem with machine learning algorithms running on the drone’s control unit, which analyze sensor data to identify patterns of icing risk and structural stress. This predictive maintenance capability enables the drone to foresee potential failures before severe damage occurs, scheduling self-repair cycles and preemptively activating heating elements — effectively preventing icing altogether.

The manufacturing process of this advanced skin blends cutting-edge flexible electronics techniques with novel material chemistry. The base polymer matrix is composed of thermoplastic elastomers and re-healable crosslinkers, optimized for elasticity and mechanical strength. Embedded conductive pathways are patterned using inkjet printing of conductive inks, while nanoscale materials are evenly dispersed to ensure consistent electrical performance. This scalable manufacturing method demonstrates the feasibility of commercial deployment without prohibitive costs.

In laboratory tests, the self-healing drone skin demonstrated exceptional resistance to mechanical damage. Under simulated real-flight environmental conditions, its tensile strength fully recovered within minutes even after being scratched or punctured. Even when exposed to simulated supercooled atmospheric water droplets, the anti-icing system maintained the surface temperature above freezing, effectively preventing ice buildup under varying wind speeds and humidity levels. Throughout the entire testing process, the sensor array remained fully functional and maintained accurate readings, proving the multimodal performance of the skin.

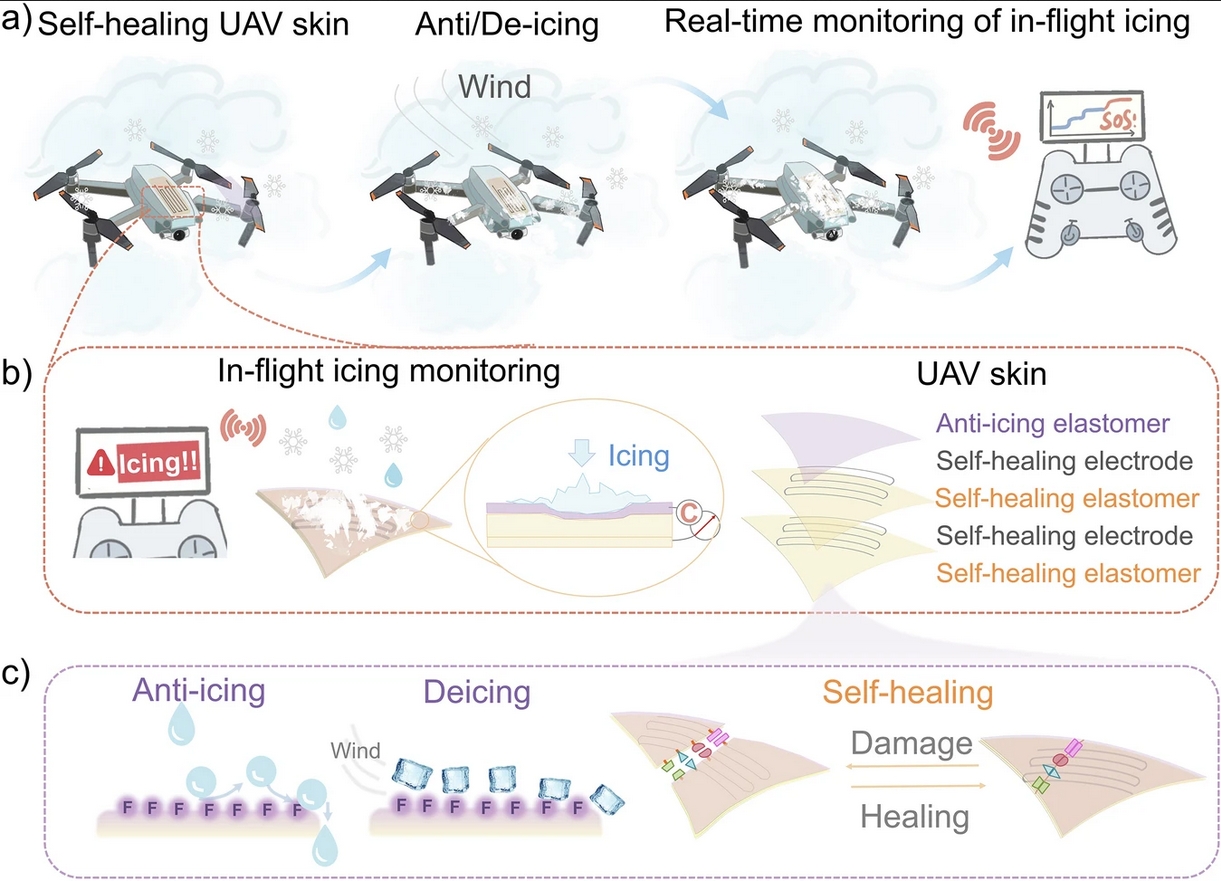

a. Self-healing intelligent drone skin for detecting and preventing in-flight icing;

b. The five-layer drone skin and in-flight icing monitoring mechanism developed by the research team;

c. The anti-icing, de-icing, and self-healing properties of the engineered drone skin.

In addition, field trials conducted on a prototype drone platform demonstrated that the intelligent skin could detect the onset of icing and autonomously activate heating zones, restoring safe flight conditions without pilot intervention. These tests confirmed the skin’s ability to maintain aerodynamic stability and sensor integrity even during rapid temperature fluctuations and harsh weather — a crucial step for drone operations in high-risk environments such as mountainous regions, offshore platforms, and polar areas.

Integrating intelligent technologies directly into the skin material itself represents a revolutionary step beyond traditional aerospace structures. Conventional aircraft structures rely heavily on separate, often bulky and cumbersome de-icing and monitoring systems. By embedding multifunctionality at the material level, this design not only reduces the overall weight of the drone but also enhances stealth and energy efficiency — factors that are increasingly critical in military, commercial, and scientific applications.

Moreover, the self-healing mechanism pushes the concept of material lifespan far beyond traditional limits, reducing maintenance cycles and downtime. This extended durability is especially vital for drones operating in remote or hard-to-reach locations, where frequent maintenance visits are impractical or prohibitively expensive. The skin’s ability to autonomously repair minor abrasions or cracks mitigates the risk of cascading failures that could otherwise jeopardize mission success.

The researchers also highlighted the potential to integrate additional functions into this platform — such as adaptive camouflage, energy-harvesting modules, or enhanced electromagnetic shielding to resist interference. The modular design approach allows customization for specific mission requirements, paving the way for a new generation of intelligent, resilient, and multifunctional drone platforms.

Looking ahead, challenges remain in scaling up production to meet industrial demands, as well as further improving the skin’s response time and energy consumption characteristics. The team is exploring advanced machine learning models to better predict icing patterns from environmental data streams, and investigating alternative self-healing chemistries that can operate under broader temperature and stress conditions without compromising flexibility.

In an era of exponential growth in drone applications — from delivery drones and environmental monitoring to defense and disaster response — the emergence of self-healing, anti-icing, intelligent skins marks a critical innovation. This research not only addresses an urgent mechanical and environmental challenge but also advances the conceptual framework of an aircraft’s skin: a dynamic, interactive interface between machine and environment that can autonomously adapt, protect, and regenerate.